TECHNOLOGIES & MATERIALS

We start with our highly skilled engineers using 2D and 3D CAD software to reverse engineer an existing pattern, and constantly check the design against the original to ensure exactness.

Our competitors still cut their material by hand, or with old obsolete stamping presses. Zervi patterns are cut out with automatic CNC machines, resulting in absolute precision and attention to detail.

Once we make a sample on one of our proprietary fabric blends, we follow our strict quality control guidelines, and only accept designs of the highest quality.

We follow strict quality control measures at each step of the process, checking individual cut panels against 2D CAD and OEM tolerences.

We hold ourselves to the strictest Japanese and American automative manufacturing guidelines, and this strict adherence results in a premium product.

Video can’t be displayed

This video is not available.

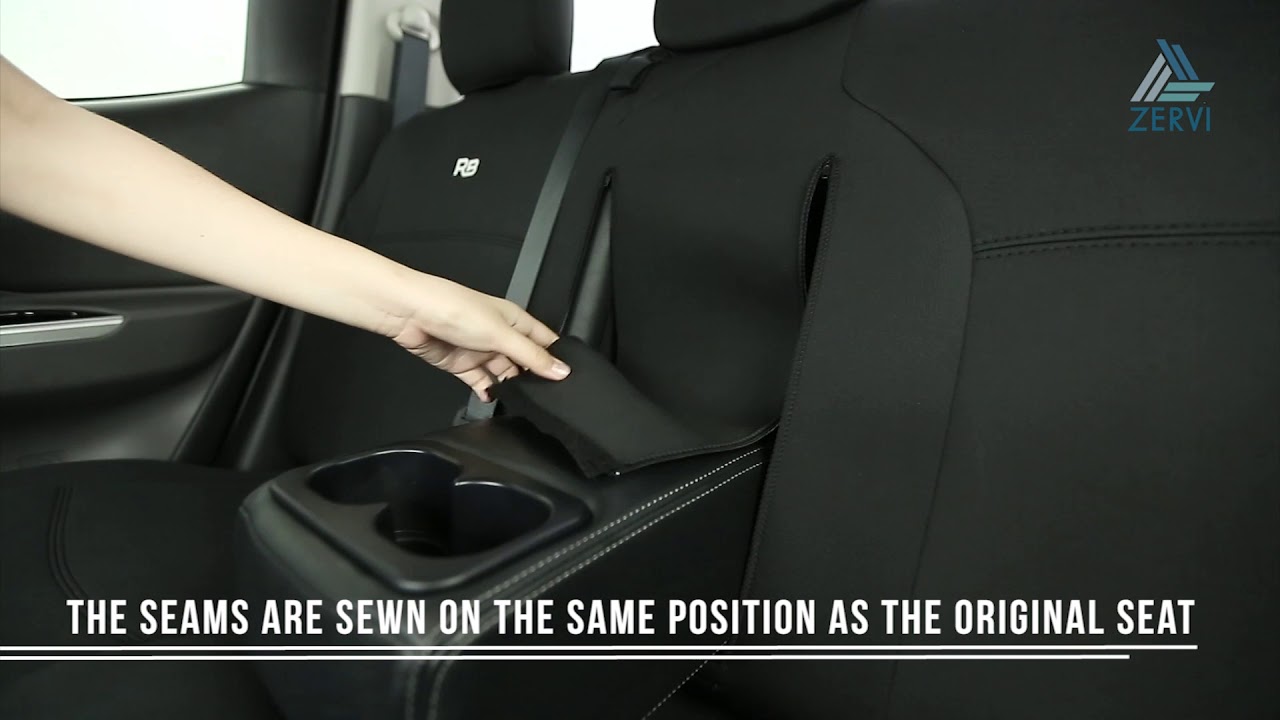

Computerised Airbag Seam

Zervi use a Duerkopp Adler computerised automotive sewing machine for all airbag seams. These are the same sewing machines that are used to sew the engineered airbag seams into the OEM seats themselves on the production line.

This machine creates barcodes for each engineered airbag seam, with information about the batch, yarn, date and operator, which allows us full accountability in the event of an airbag deployment.

Over the past 10 years, Zervi have quickly become one of the leading manufacturers of neoprene to the automotive industry in Australia, whilst also offering canvas, PVC, leather, and may other high quality materials. All of Zervi's materials are tested to the strictest international automotive standards, meeting and exceeding test methods from many of the largest automotive manufactureres in the world.

Video can’t be displayed

This video is not available.

OEM Quality Neoprene

Zervi neoprene seat covers enhance your on board experience. Made of a similar material to a typical wet suit, Zervi neoprene is water-resistant, durable, and long lasting. This results in a beautiful cover that offers both aesthetics and function, and will keep your car safe from anything life will throw at it.

The neoprene is proprietary Zervi technology, and is sourced from its dye and yarn, and then knitted and laminated to our specifications, resulting in a world class neoprene that is suitable for any number of uses from automotive, to marine or commercial transport.

Zervi also use custom designed heat press embossed patterns, to add a point of unique difference on the finished goods. Each customer can design their own emboss pattern, which they can use on all of their covers and accessories going forward.

In addition to heat-press capabilities, Zervi has an in-house embroidery machine, and can offer custom embroidery in matching colours, to any of our internal products, to allow you to show off your brand in the highest quality.

Automotive Grade Canvas

Not only is Zervi one of the leading manufacturers of neoprene, but we are experts in tailored canvas accessories as well.

We make canvas covers for a variety of industries, including but not limited to:

4x4’s & off-road vehicles - Farming & mining - Trade specific industries - Camping - Lifestyle Accessories -

Our expertise and technology allows us even to supply fire resistant canvas covers for emergency services, and products specifically engineered to Military & Defence Force standards.

OEM quality Leather and trim

- Zervi are set up to do large-scale leather production and trim

- Cut kits for trimmers to sew and finished trim ready to install

- Highly specced and tested leather to meet strict OEM international standards

- Colour and grain matching to meet any leather requirements

- Sourcing from world class leather facilities in Italy and Europe

- Leather to match any requirements and price points

- Support for anything from large volume fleets to trim for consumers